LEAP - MANUFACTURING TRACK

OPPORTUNITIES ACCELERATED

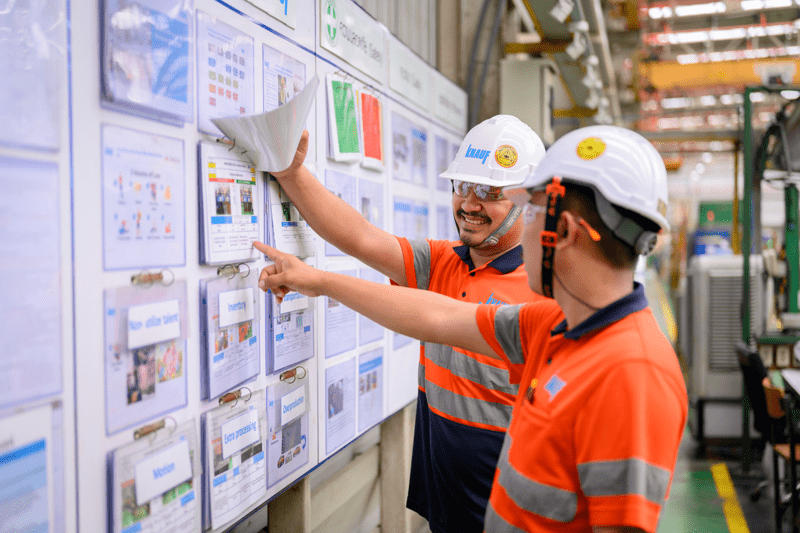

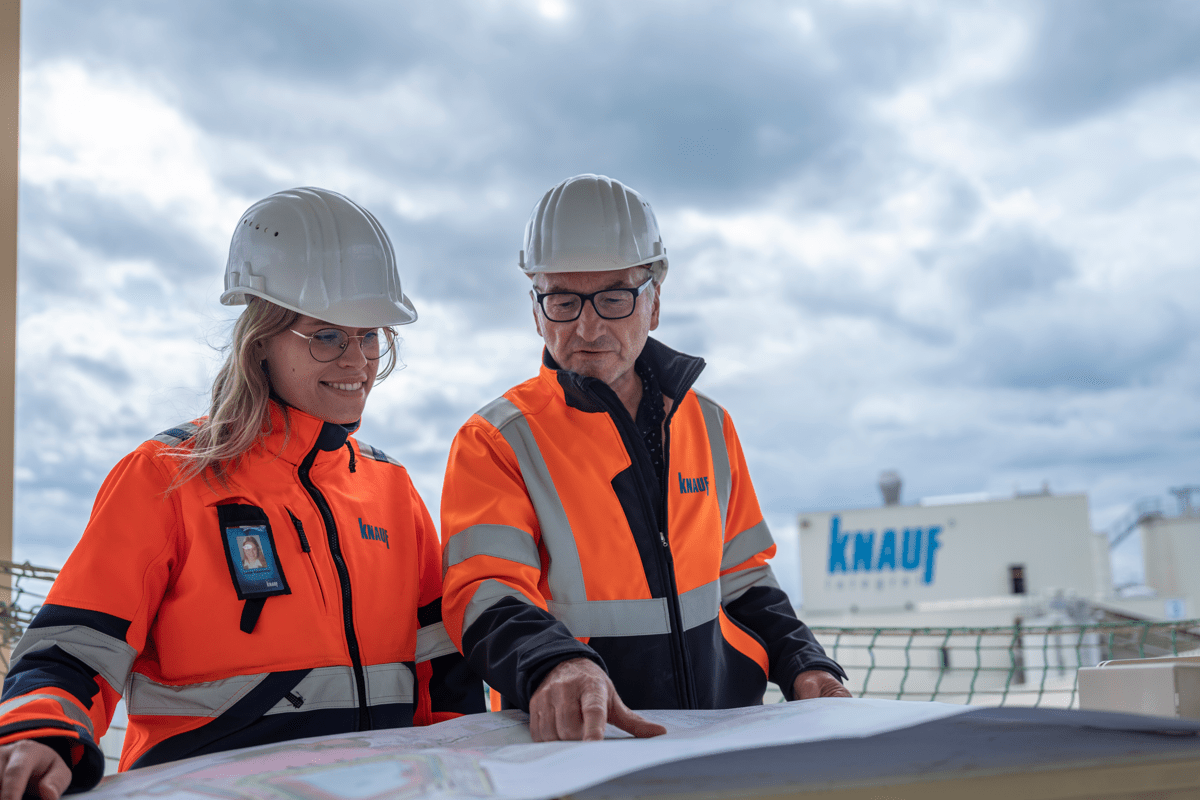

As a Manufacturing Track trainee, you will embark on an immersive experience at the core of Knauf Gypsum APAC’s production processes, providing a comprehensive understanding of the complexities in the manufacturing sector. You will:

The duration and department rotations will vary between countries, giving you a comprehensive understanding of our manufacturing and commercial strategies.

This track is designed to equip you with the technical skills and strategic insights needed to oversee and optimize manufacturing operations effectively, preparing you to become a future leader.

Role & Responsibilities

-

Production Management

Oversee the production process to ensure efficiency and quality standards are met.

-

Process Optimization

Identify and implement improvements to enhance production efficiency and reduce costs.

-

Quality Control

Ensure products meet quality standards through regular inspections and testing.

-

Maintenance

Coordinate maintenance activities to minimize downtime and ensure smooth operation of machinery.

-

Health & Safety

Promote and ensure adherence to health and safety regulations within the manufacturing environment.

-

Inventory Management

Monitor inventory levels and manage stock to prevent shortages and excess.

-

Continuous Improvement

Identify and implement process improvements to enhance supply chain efficiency.

-

Sales Strategy

Assist in the development and implementation of sales strategies to achieve revenue targets.

Key Activities

*The specific roles, responsibilities, and key activities that trainees will experience may vary by country.

-

Production Planning

Assist in planning and scheduling production runs to meet demand.

-

Process Analysis

Analyze production processes to identify bottlenecks and areas for improvement.

-

Quality Inspections

Conduct regular quality checks and address any issues that arise.

-

Maintenance Scheduling

Schedule and oversee maintenance activities to keep equipment in optimal condition.

-

Safety Audits

Conduct safety audits and implement corrective actions to ensure a safe working environment.

-

Learning & Development

Participate in learning opportunities and apply knowledge to practical situations.

Expertise You Will Gain

- Efficient Production Management

- Quality Control Techniques and Standards

- Technical Skills

- Health and Safety Best Practices

- Effective Inventory Control

- Project Management

- Business Processes

Hear from our Trainees...

-

The LEAP program has been a transformative journey that has allowed me to develop key skills essential for professional growth. I have gained stronger communication and collaboration abilities, learned how to navigate challenges through problem-solving, and applied effective project management practices across different rotations. This diverse exposure has expanded my understanding of the business and strengthened my ability to work with people from various backgrounds. I believe these experiences have prepared me to make meaningful contributions to the company while continuing to grow personally.

Peerapat Piriyakitpaisarn

LEAP 2024 Trainee - Thailand

-

Looking to kickstart your career in manufacturing? Knauf LEAP 2025 Program is a great place to start. I have gained hands-on experience through cross-department rotations, received valuable training, and felt truly supported in my development. One exciting part for me is joining new projects: I start knowing nothing, but each time I learn so much along the way. It is a fast-paced, enriching journey that helps you build real skills and confidence. I highly recommend it to anyone ready to take their first big step!

Ajeng Almira Tarisha

LEAP 2025 Trainee - Indonesia

-

The LEAP program has given me a platform from which I can make meaningful impact to the plant’s operations, whilst having guidance and support from the manufacturing and management teams. The flexible nature of the program has allowed me to explore areas that interest me and in turn leverage my strengths to design improvements for the plant.

Jahal Michael Adamovskis-Kraus

LEAP 2025 Trainee - Australia

-

As a LEAP trainee, I feel strongly supported, thanks to our facilitators who work hard to create a nurturing environment where all feedback is always welcome. Moreover, I have found the networking with other trainees across the APAC region surprisingly beneficial than expected. It is inspiring that, even with our diverse backgrounds, we are all on the same journey of continuous improvement-always seeking ways to get better and learn new things.

Romchat Lertkamolsin

LEAP 2025 Trainee - Thailand

-

Being in this management trainee program has been a game-changer for me. It's not just about sitting in a classroom—I've been given a chance to jump in and get real-world experience. The projects have been challenging, and I've learned a ton, not just about business, but about myself too. I'm really glad I've had this experience, and I'm excited for what's next.

Vittorio Alison

LEAP 2025 Trainee - Indonesia